Introduction

For businesses, having durable, secure and cost-effective packaging boxes is essential. fluted cartons, also known as corrugated cardboard boxes, have become a popular choice in the packaging industry for their versatile applications and eco-friendliness. In this article, we will dive into the different aspects of fluted cartons, from their structure, manufacturing process, to their benefits and applications.

The Structure of Fluted Cartons

Fluted cartons consist of three layers: an inner liner, an outer liner, and a medium layer which creates the characteristic flutes. The flute layer varies in thickness and depth, depending on the specific needs of the product inside and the intended packaging usage. The most common flute types include A-flute, B-flute, C-flute, E-flute and F-flute, with A-flute being the thickest and most durable and F-flute being the thinnest and most flexible.

Manufacturing Process of Fluted Cartons

Fluted cartons are made by bonding together multiple layers of paperboard using adhesives. The process starts with the corrugation of the medium layer into the waves, which is then sandwiched between the liner sheets, forming a single sheet of corrugated cardboard. The cardboard sheet is then cut and folded into different box shapes and sizes, depending on the product specifications.

The Benefits of Fluted Cartons

Fluted cartons offer multiple benefits for businesses in terms of packaging, shipping, storage, and eco-friendliness.

- Strength and Durability: Fluted cartons are highly resistant to impact, crushing and other forms of damage during transportation, which ensures the safety and integrity of the products inside.

- Cost-effectiveness: Fluted cartons are cheaper than other packaging materials such as plastic and metal, which reduces the overall production costs.

- Lightweight and easy to handle: Despite their strength, fluted cartons are lightweight and easy to handle, which saves time and effort during packaging and shipping.

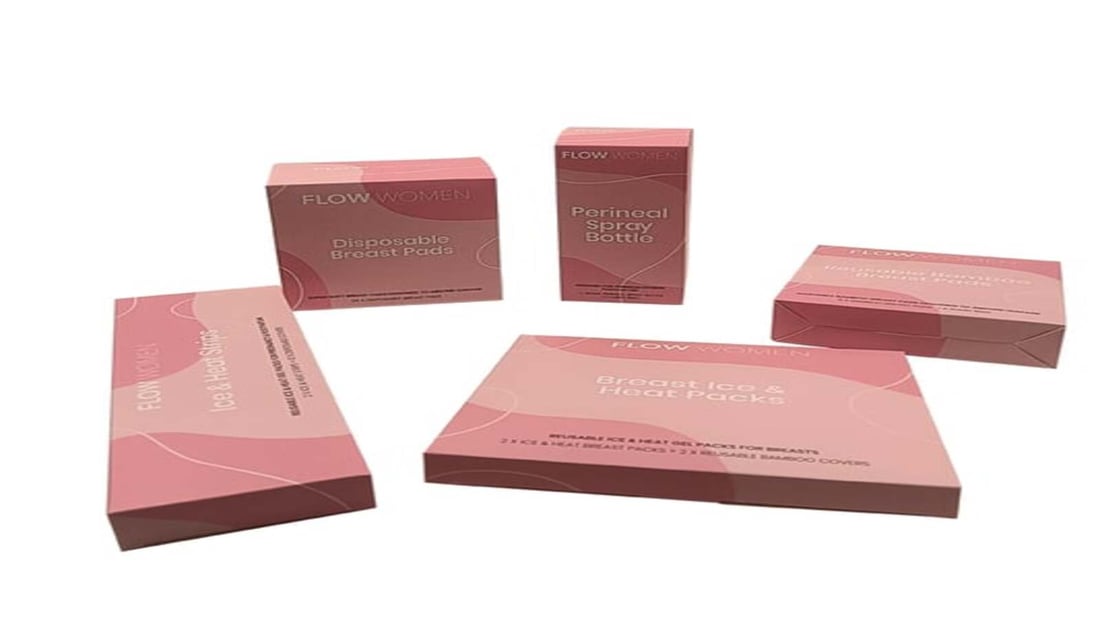

- Customizability: Fluted cartons can be designed and printed with different colors, logos and graphics, which can enhance brand recognition and visual appeal.

- Eco-friendliness: Fluted cartons are made from recycled paperboard and are recyclable, which reduces the environmental impact and promotes sustainability.

Applications of Fluted Cartons

Fluted cartons have a wide range of applications in various industries and sectors, including:

- Food and beverage: Fluted cartons are commonly used for packaging fruits, vegetables, dairy products, frozen foods, and beverages due to their moisture resistance and insulation properties

- Electronics: Fluted cartons provide cushioning and shock absorption for fragile electronic devices such as computers, laptops, and smartphones during shipping and handling.

- Pharmaceuticals: Fluted cartons are used for packaging medicines, vaccines, and medical equipment, which require high-level hygiene and protection.

- Retail and e-commerce: Fluted cartons are ideal for shipping and storing products of different shapes and sizes, such as clothing, books, toys, and home appliances.

Choosing the Right Fluted Cartons

Choosing the right fluted cartons depends on various factors such as the type and size of the product, the shipping conditions, and the budget. Some of the key considerations include:

- Flute type and thickness: The appropriate flute type and thickness should be chosen based on the weight and fragility of the product.

- Size and dimensions: The carton should be sized according to the product dimensions to ensure a snug fit and minimal movement inside.

- Printing and branding: The printing quality, colors, and design should align with the brand's image and message.

- Additional features: Some fluted cartons come with additional features such as tamper-evident seals, tear strips, and handles, which can enhance the security and convenience of the packaging.

Maintaining Fluted Cartons

Proper maintenance of fluted cartons can extend their lifespan and ensure their quality. Some tips for maintaining fluted cartons include:

- Store them in dry and clean spaces to avoid moisture and contamination.

- Avoid overloading or stacking them beyond their weight limit, which can cause deformation and damage.

- Recycle them after use to reduce waste and promote sustainability.

The Future of Fluted Cartons

The use of fluted cartons is expected to increase in the coming years, due to their growing popularity, and the increasing demand for eco-friendly and cost-effective packaging solutions.

Moreover, advancements in technology and innovation are paving the way for further improvements in the strength, durability, and design of fluted cartons, making them an even more attractive option for businesses.